Injection molding of plastic trays is thermoplastic injection molding, which is to melt plastic materials and then inject them into the film cavity. Once the molten plastic enters the mold, it is cooled and molded into a certain shape according to the mold cavity. The resulting shape is often the final product and no further processing is required before installation or use as a final product. Many details, such as overhangs, ribs, and threads, can be formed in a single operation in injection molding.

Injection plastic tray performance:

a. It can be used in (-35°~40°) environment, and its performance remains unchanged;

b. Excellent impact resistance, no sparks due to friction. Not easy to burn. Can not afford static electricity;

c. No rust, no water accumulation, flood resistance, water resistance, washing resistance, easy to clean;

d. The service life is much longer than that of wooden pallets, no maintenance is required, it is resistant to falling and collision, it can be recycled, and it meets the requirements of environmental protection.

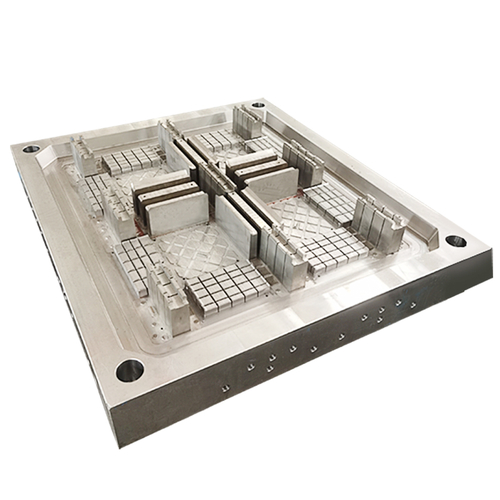

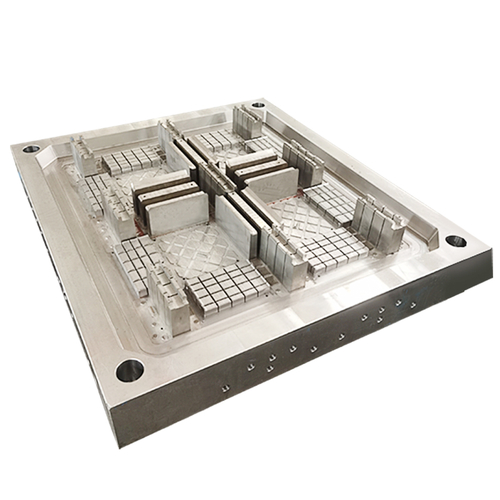

Customized Plastic Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

Customized Plastic Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى