1. Extrusion molding method: The pallet mould produced by extrusion molding method are all assembled. That is, using extruder, machine head and other equipment to extrude the slats used as the upper and lower panels and the I-shaped connecting plate with double wings as the connection support, and then assemble. The emergence of wood-plastic composite materials has promoted the development of extrusion molding plastic pallets. It uses natural plant fibers and waste plastics as the main raw materials, so that the plastic pallet has both a woody feel, and the advantages of water resistance and pest control, and can be planed, sawed and nailed.

2. Vacuum forming method: There are two types of plastic trays produced by vacuum forming method: single-sided and double-sided. Single-sided blister trays are mostly used for packaging and transportation of small motors and wire reels. They have developed rapidly recently and are mainly dedicated. The double-sided blister trays are assembled and divided into two forms: the upper half is an extruded fixed-length and fixed-width plastic sheet, the lower half is a large vacuum blister product; the upper and lower half are large vacuum blister product. This method requires large vacuum forming equipment, the equipment cost is low, the mold cost is also low, but the product wall thickness is not uniform.

3. Extrusion-hollow blow molding method: The extrusion-hollow blow molding of plastic trays is similar to the general blow molding method of hollow products, but because the product is large and double-sided, it requires a larger size. Extruders, clamping machines and molds, etc., but the input of molds and equipment is much smaller than that of injection molding, the process is simple, and the cost is low, but the products are not compact, the flatness is poor, and it is difficult to control the uniform wall thickness.

4. Injection molding method: The plastic pallet products produced by the injection molding method are flat, smooth, crisp and dense, and have a large degree of freedom in product design. They are divided into double-sided integral plastic pallets and double-sided assembled plastic pallets.

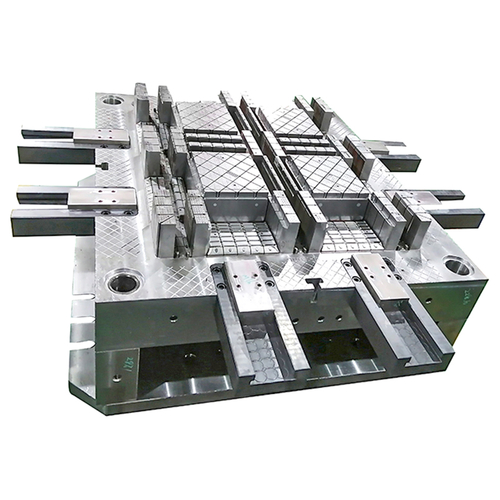

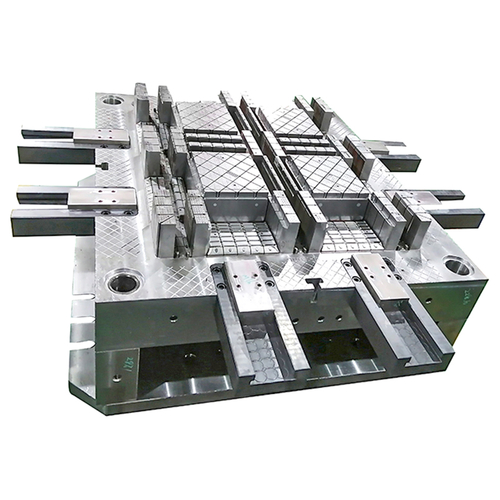

Customized Heavy Duty Logistics Single Face Pallet Mould

Customized Heavy Duty Logistics Single Face Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى