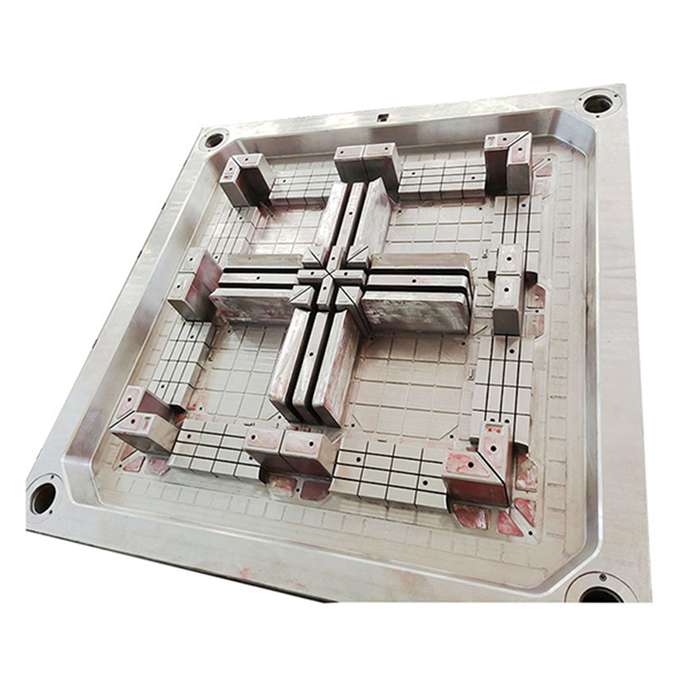

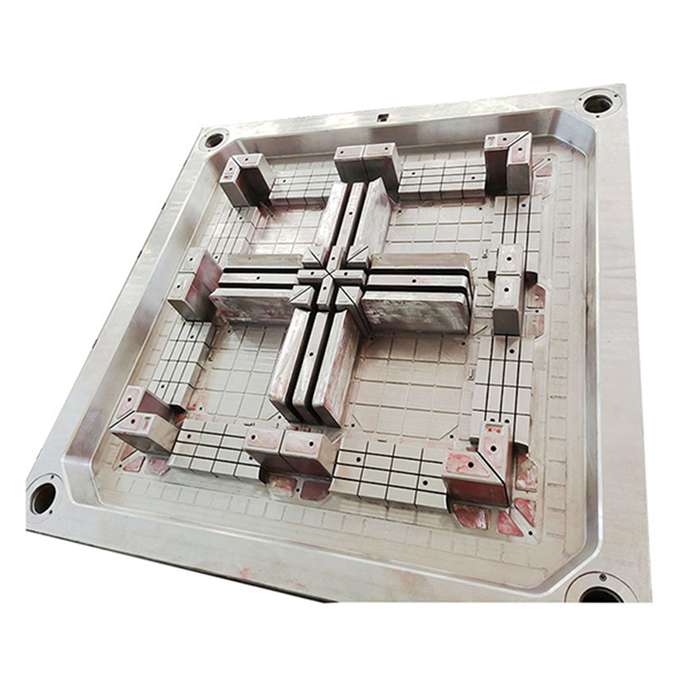

1. Use the correct steel for formwork and plastic pallet mold body steel, and choose high toughness steel for some part inserts. For example, if we need to make a 2-cavity box mold, then we need to use 32HRC pre-hardened steel as the formwork base. We have to choose the right steel for durable mold parts.

2. Select the correct quenching treatment for the core, cavity, slider and insert to control the hardness of the steel. Generally, the steel should not be too hard. Sometimes, the hardness of the mold is not very high, because it is easy to crack.

3. The guide system and moving area of the box mold must adopt precision machining technology. Manual work is not acceptable, otherwise there will be problems with the guidance system and moving areas at runtime.

4. The hot runner system is very important for large and light boxes. So we will make the mold flow analysis software for the box mold of the hot runner system. In order to fill the plastic material in a balanced manner, we need a very special hot runner system.

5. To reduce cycle time to save cost, we must make the cooling to the best effect, for durable plastic box mold, we should use mold-max with excellent cooling channel design in molding area, for single use crate , we need to use tempered steel with an excellent cooling system design.

6. Of course, the design of the plastic box mold is the top priority, it is best to use a mechanical system when the box mold is ejected, so that the ejection action can be made when the mold is opened. Of course, if your machine can use 2 hydraulic actions at the same time, then you can eject when the mold is opened.

7. For various molds, the basis for high-speed operation is that the molds are precision-machined and the moving parts are guided accurately, otherwise, the high-speed performance of the mold is impossible.

8. The handle part on the plastic turnover box needs to solve the ventilation problem: this is an important problem. When the turnover box is loaded and people carry the turnover box, the 2 handle area will be the largest stress concentration point. If the venting in this area is not perfect on the mold, there will be a very obvious seam line. Damage always comes from this line.

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)