1. injection pallet

injection pallet mould are the largest variety of plastic pallets produced in China.

Since the 1980s, China has introduced foreign equipment to produce injection pallet, but the market has not been opened due to various factors such as cost. It has created conditions for the expanded production of general-purpose industrial plastic pallets.

2. Blow Molding Tray

Affected by cost and process conditions, there are relatively few manufacturers in China that use the blow molding process to produce plastic pallets. Made of high molecular weight high density polyethylene (HWMHDPE), both mechanical and manual forklifts can be used, and the double-sided pallet can be used on both sides, extending the service life.

Plastic pallets are classified by application and industry: export plastic pallets, intermodal plastic pallets, moisture-proof plastic pads, moisture-proof plastic pallets, forklift plastic pallets, shelf plastic pallets, logistics plastic pallets, food plastic pallets, beer plastic pallets, beverage plastic pallets, chemical industry Plastic pallets, tobacco plastic pallets, mechanical plastic pallets, electronic plastic pallets, salt industry plastic pallets, stacking plastic pallets, intermodal standard plastic pallets, port plastic pallets, container plastic pallets, etc.

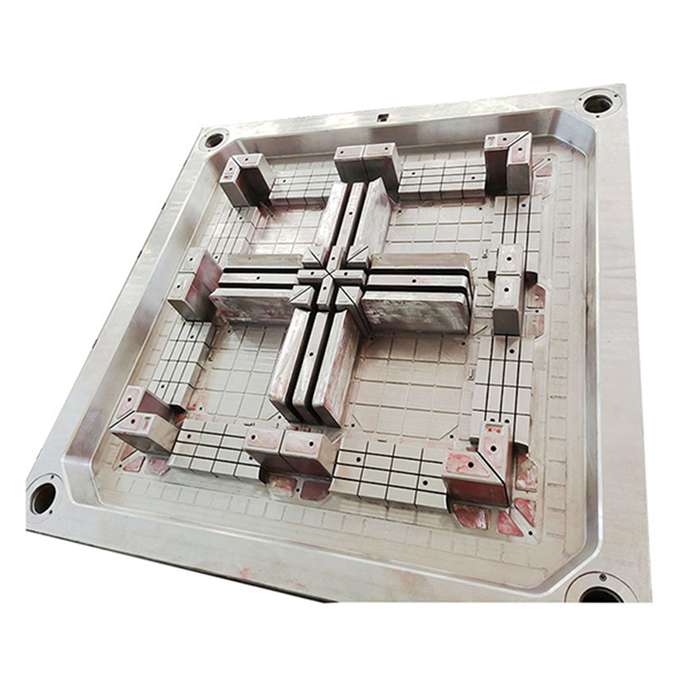

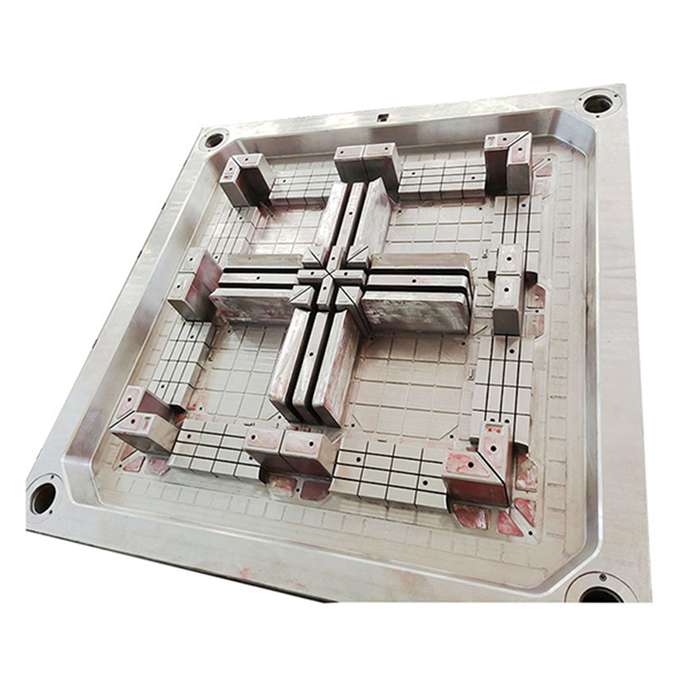

Smooth Surface Plastic Pallet Mould

Smooth Surface Plastic Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)