In the world of logistics and supply chain management, efficiency is key. It is crucial for companies to find ways to optimize their operations and reduce costs while ensuring the safe and reliable transportation of goods. One area where significant improvements can be made is in the use of plastic pallets and their moulds.

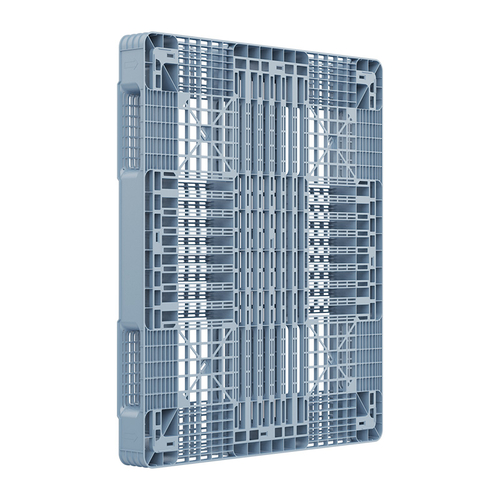

Plastic pallets have gained popularity in recent years due to their numerous advantages over traditional wooden pallets. They are lightweight, yet incredibly durable, offering a higher weight capacity and better resistance to damage. Plastic pallets are also resistant to moisture, chemicals, and pests, which means they can be used in a wide range of industries, including food and pharmaceuticals. Furthermore, plastic pallets can be easily cleaned, making them more hygienic and reducing the risk of contamination.

But what makes plastic pallets truly efficient and sustainable is the role of plastic pallet moulds. These moulds are used in the manufacturing process to shape the plastic material into the desired pallet design. They play a crucial role in ensuring consistency and quality while also optimizing production.

One of the key advantages of plastic pallet moulds is their ability to produce pallets with precision. The moulds are designed to create pallets with specific dimensions, ensuring that they fit seamlessly into automated systems and cargo containers. This precision eliminates the need for manual adjustments during loading and unloading, saving time and labor costs. By reducing handling time, companies can improve efficiency, reduce the risk of accidents, and increase overall productivity.

Moreover, plastic pallet moulds offer a high level of customization. They can be designed to include features such as reinforced corners, anti-slip surfaces, and stackable designs. This flexibility allows companies to tailor pallets to their specific needs, resulting in better protection for goods during transportation. Customization also contributes to reducing product damage, which can save companies substantial amounts in replacement costs.

Another significant advantage of plastic pallet moulds is their durability and longevity. Once the mould is created, it can produce thousands, if not tens of thousands, of identical pallets. This ensures consistency in quality and eliminates the need for frequent replacements. Wooden pallets, on the other hand, tend to wear out and break more quickly, requiring regular maintenance and replacement, which adds to costs and increases waste.

When it comes to sustainability, plastic pallet moulds offer several benefits. First and foremost, plastic pallets are recyclable. At the end of their life cycle, they can be melted down and reformed into new pallets or other plastic products. By adopting a closed-loop recycling system, companies can reduce their environmental impact and contribute to a more circular economy.

Additionally, the use of plastic pallets reduces the demand for wooden pallets. This helps to conserve forests and reduce deforestation, which is a major environmental concern. The carbon footprint of plastic pallets is also generally lower than that of wooden pallets, as they require less energy to produce and transport due to their lighter weight.

In conclusion, China plastic pallet moulds play a crucial role in elevating efficiency and sustainability in the logistics and supply chain industry. By enabling the production of high-quality plastic pallets with precise dimensions, customization options, and long-lasting durability, these moulds contribute to streamlining operations, reducing costs, and protecting goods during transportation. Furthermore, plastic pallets and their moulds are environmentally friendly, as they are recyclable and help to reduce deforestation and carbon emissions. Overall, the adoption of plastic pallet moulds is a positive step towards a more efficient and sustainable logistics industry.

English

English عربى

عربى