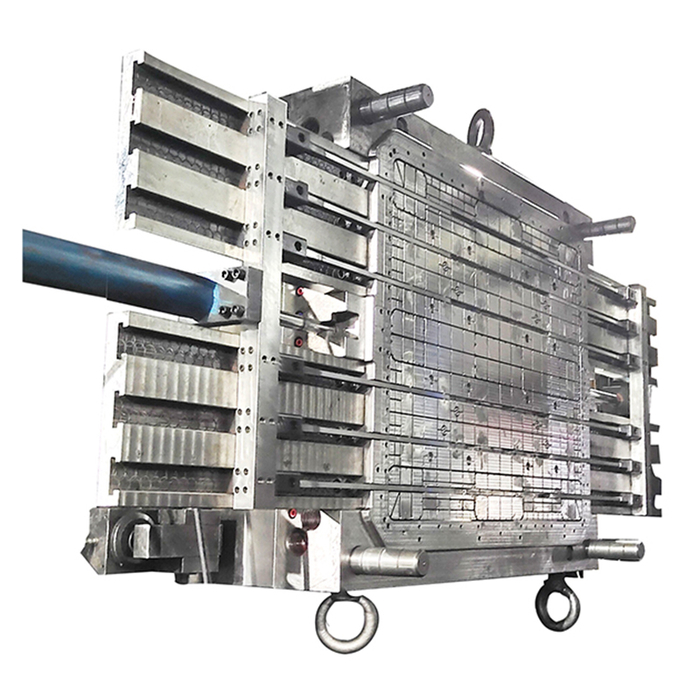

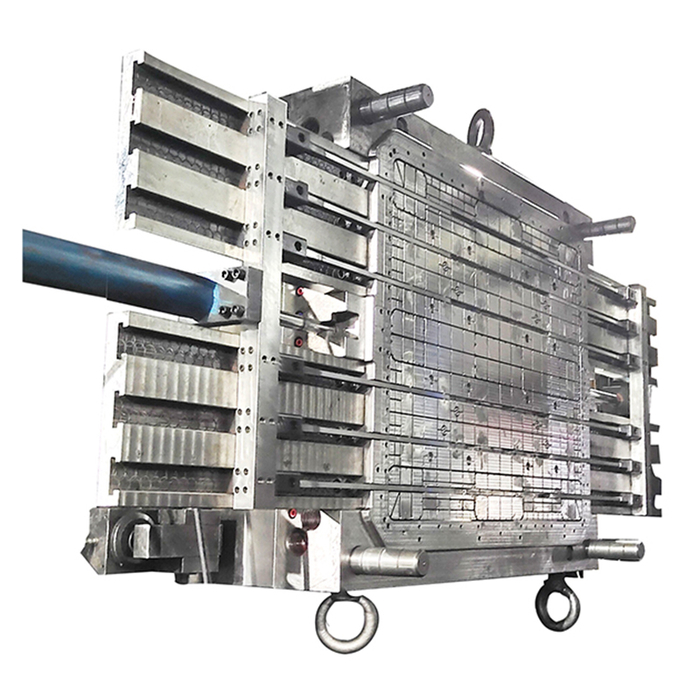

A light duty pallet mold is a type of mold that is used to produce lightweight pallets that are designed for lighter loads or smaller items. Pallet molds are used in the manufacturing process of pallets, which are flat structures used to support goods during transport and storage.

Light duty pallet molds are typically made from high-quality steel and are designed to withstand the high pressures and temperatures required for the molding process. The molds are designed with a cavity that matches the shape and size of the pallet, and can be customized to produce different types of pallets with unique features and specifications.

The production process for light duty pallets typically involves injecting molten plastic or other materials into the mold cavity under high pressure. The plastic is then allowed to cool and solidify, forming the pallet shape. Once the pallet is complete, it can be removed from the mold and trimmed to the desired size.

Light duty pallets are often used in industries such as food and beverage, pharmaceuticals, and retail, where lighter loads are transported and stored. They are designed to be durable, lightweight, and easy to handle, making them an ideal solution for many applications.

The advantages of using a light duty pallet mold include the ability to produce high-quality pallets with consistent dimensions and features, and the ability to customize the design of the pallet to meet specific application requirements. Additionally, the use of a mold can help to reduce production costs and increase efficiency in the manufacturing process.

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى