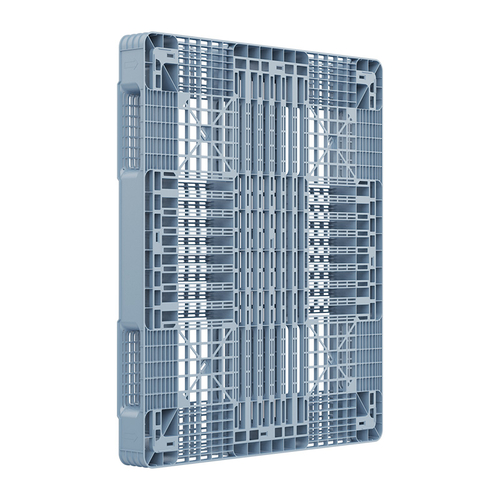

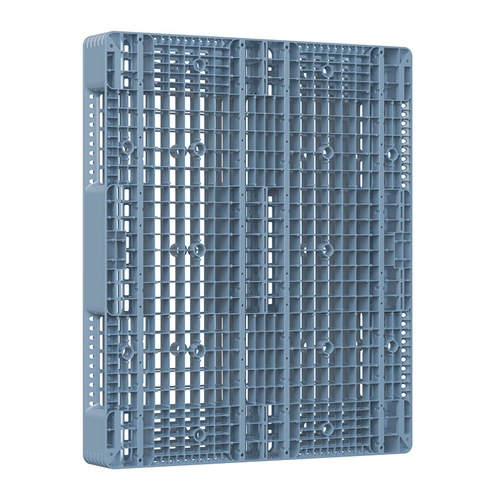

In today's rapidly developing industrial era, the logistics industry is facing challenges and opportunities. In order to meet the market demand for efficient, environmentally friendly and durable logistics equipment, heavy duty pallet mould came into being and became an important branch of the plastic mold industry.

Innovation is the core driving force for the development of the heavy duty pallet mould industry. With the advancement of science and technology, new materials, new design concepts and advanced manufacturing technologies continue to emerge, providing broad space for the development of heavy duty pallet mould. For example, by using new polymer materials, the load-bearing capacity and wear resistance of heavy pallets can be improved; by optimizing mold structural design, production efficiency can be improved and costs reduced; by introducing intelligent manufacturing technology, the automation and information of the mold manufacturing process can be realized change.

The application of high-tech equipment provides strong guarantee for the manufacturing of heavy duty pallet mould. In the mold manufacturing process, high-precision CNC processing equipment, advanced measurement technology and automated production lines are used to ensure the accuracy and quality of the heavy duty pallet mould. In addition, by introducing advanced CAD/CAE/CAM systems, rapid iteration and optimization of mold design can be achieved, the research and development cycle can be shortened, and the market response speed can be improved.

In the design and manufacturing process of heavy duty pallet mould, the integration of innovation and high technology has brought revolutionary changes to the industry. For example, by adopting a modular design concept, the production cost and maintenance difficulty of heavy duty pallet mould can be reduced; by introducing simulation technology, the performance and service life of molds can be predicted during the design stage; by implementing intelligent manufacturing, real-time monitoring and remote monitoring of the production process can be achieved control.

Although the heavy duty pallet mould industry has achieved remarkable results, it still faces some challenges. For example, as market competition intensifies, customers have higher and higher requirements for the performance, quality and price of molds; as environmental regulations become increasingly stringent, waste disposal and energy conservation and emission reduction during the mold manufacturing process have become urgent issues to be solved. Therefore, the industry needs to continue to innovate and introduce new technologies to meet these challenges.

The heavy duty pallet mould industry will usher in more development opportunities. With the advancement of global economic integration, the demand for heavy duty pallet mould in the international market will continue to grow. In addition, with the development of emerging technologies such as the Internet of Things, big data and artificial intelligence, Heavy Duty Pallet Mold will achieve a higher degree of intelligence and automation. In this process, innovation and high technology will continue to play a key role in driving the industry forward.

Heavy duty pallet mould ,is an important branch of the plastic mold industry. In the future development process, the industry needs to continuously explore new technologies, new concepts and new models to meet the changing needs of the market and make greater contributions to the development of the global logistics industry.

English

English عربى

عربى