If you're looking for industrial pallet molds, there are plenty of options to choose from. There are injection tray molds, hot runner systems and PE/PP tray molds. All of these molds are perfect for packaging products. Whether your product requires a pallet that fits a small space or a pallet that fits a large one, you'll find industrial pallet molds fit the bill.

Injection tray mold

Blow-molded trays are lightweight and strong. They are impact resistant and can withstand temperatures up to 40 degrees Celsius. They can be used in cold chain supply procedures and are not prone to breakage. Injection-molded trays are generally stronger, but they do not stack as high as blow-molded trays.

Plastic trays are made from a variety of plastics. The process used to make them involves different considerations, including the size of the pallet, the material used to make it, and the weight of the pallet. Once these factors are determined, the plastic forms the mold. During the injection process, the virgin plastic is melted, colorants are added, and then injected into the mold.

physical education

When designing a PE industrial pallet mold, the first step is to collect the required data about the pallet product. This data will be used to generate the 3D model. Once the design is complete, order the steel needed for the mold. The steel used to make the mold must have a high hardness level. One way to get the best results is to choose a pre-hardened acid-resistant steel. This steel has excellent corrosion resistance and good polishability.

After the molding process is complete, the trays must be stored in a dry, well-ventilated environment. Ideally, pallets should be stored in a covered storage shed to avoid moisture affecting the wood surface. A well-ventilated shed also improves air circulation, which can help prevent mold growth.

polypropylene

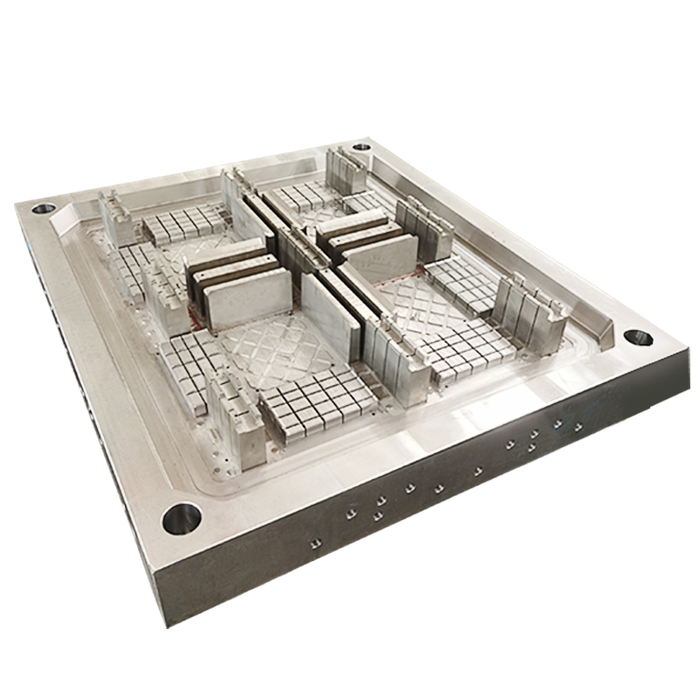

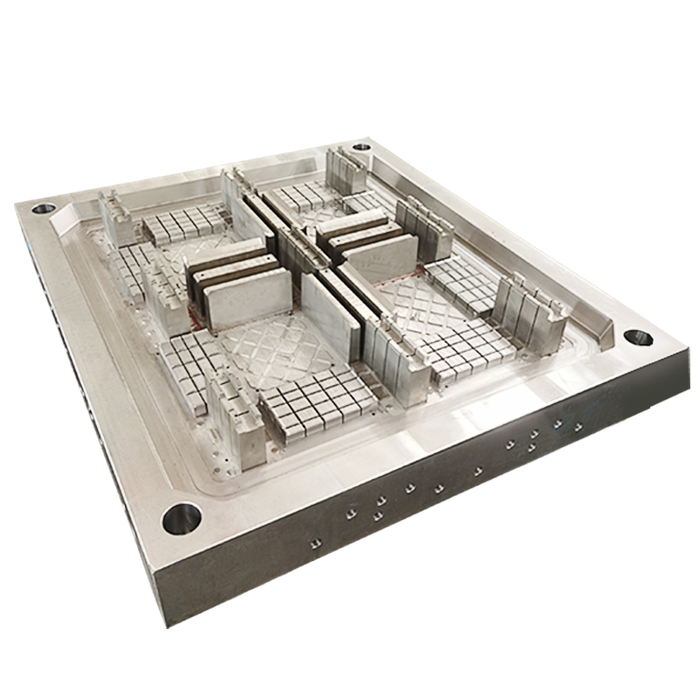

PP industrial pallet moulds are used to produce plastic pallets. The dimensions of this mold are shown in Figure 1. The thickness of the rib is 3.4 mm and varies according to the draft angle. The mold is equipped with twelve fill gates, each with a diameter of 7.0 mm and a height of 20 mm. The plastic material for injection moulding is recycled polypropylene (PP). Cool complex features with a baffled cooling flow system. Molds are designed using a mold flow analysis program called Moldex3D.

Plastic pallets can be produced by injection molding. Various techniques are used for this purpose. PP pallet molds are one of the most common types of plastic pallets. They can be made of HDPE, PE or PP plastic.

Hot runner system

A hot runner system is a tool that controls the flow of plastic into a mold cavity. It uses a mechanical shut-off pin that opens and closes at the nozzle tip to achieve the desired flow pattern. The system enables faster cycle times and automation. It can also allow wider processing windows.

A hot runner system is expensive to purchase, but it pays off in the long run, reducing plastic waste and cycle time. It also allows for the best return on any project.

chemical solution to kill mold

There are many different types of chemicals that can be used to kill industrial pallet molds. Depending on the nature of the mold, some chemicals are more effective than others. Some of these chemicals are even approved for use in food packaging. These chemicals can be applied to wooden pallets simply by dipping them into the solution. Once applied, they provide up to three months of protection against mold growth.

Another option is to apply a fungicide to the tray. Fungicides are very effective at preventing mold growth, but they are not as effective on wood that is already moldy. A great way to prevent mold from growing on your pallets is to keep them dry and free of moisture.

their use

Industrial pallet moulds are designed to manufacture plastic pallets. There are various methods of pallet manufacturing, including rotational molding and injection molding. Both methods use high-pressure air to force the plastic into the mold cavity. The process produces plastic pallets with a high strength-to-weight ratio. Industrial pallet molds are low cost. Typically made from HDPE, they are durable, washable, non-corrosive and recyclable.

The positioning of the mold is a complex process. Many factors must be considered during the design phase, such as the contact press and how to handle the pallet mold. The type of press is also important. Many plastic presses are designed with complex shapes and require careful handling. Overhead cranes or crane hooks are often used for final positioning.

Customized Plastic Pallet Mould

Customized Plastic Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى