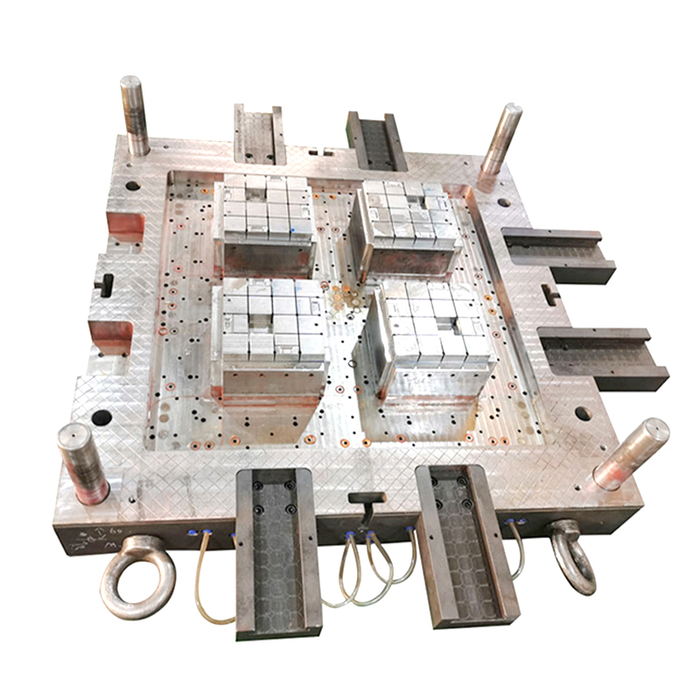

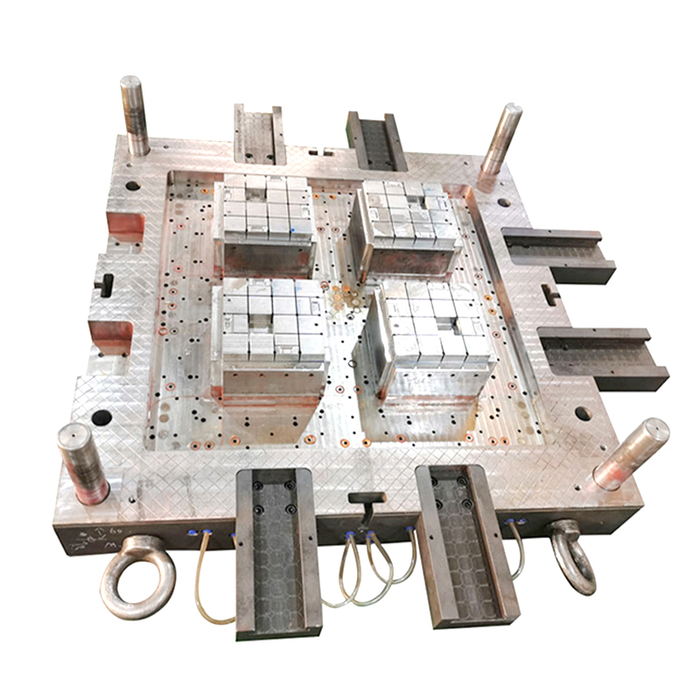

An injection pallet mold is a type of mold used in the injection molding process to manufacture pallets. Injection molding is a manufacturing process in which a material, such as plastic, is heated until it melts and is then forced into a mold under high pressure. The mold is designed to shape the material into the desired form, in this case, a pallet. Once the material cools and solidifies, the mold is opened, and the pallet is removed. The mold is then used again to produce additional pallets. Injection pallet molds are typically made of steel or aluminum, and are precision-engineered to produce high-quality pallets with consistent dimensions and minimal defects.

Injection pallet molds are used in the manufacturing process of injection molding to produce pallets. Some of the key uses of injection pallet molds include:

High-volume production: Injection molding is a highly efficient process that allows for high-volume production of pallets with minimal labor and time.

Consistency: Injection pallet molds are precision-engineered to produce pallets with consistent dimensions and minimal defects, ensuring that the pallets produced are of high quality.

Cost-effective: Injection molding is a cost-effective process that can produce pallets at a lower cost than other manufacturing methods.

Durable: Pallets produced using injection molding are typically made of durable materials that can withstand heavy loads and harsh conditions, making them ideal for use in a variety of settings.

Customization: Injection pallet molds can be designed and created to produce a wide range of pallet sizes, styles, and designs to meet specific requirements and needs.

Recycling: Many of the materials used in injection molding are recyclable, which helps to reduce waste and promote sustainability.

Efficiency: Injection molding process is efficient, fast and can produce large quantity of pallets in a short time.

These are some of the common uses of injection pallet molds. However, it may vary based on the design and materials used in the mold, as well as the specific application for which the pallets will be used.

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)