When you find an industrial pallet mold in your warehouse, the first thing to do is to determine what caused it. Several factors can contribute to the growth of this mold, such as moisture levels and the presence of oxygen. This information can help you identify the source of the problem and decide how to fix it.

plastic

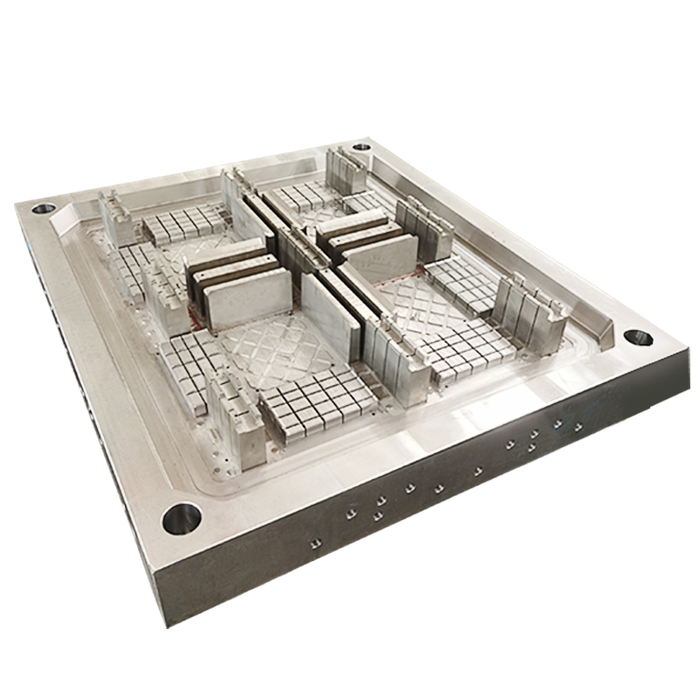

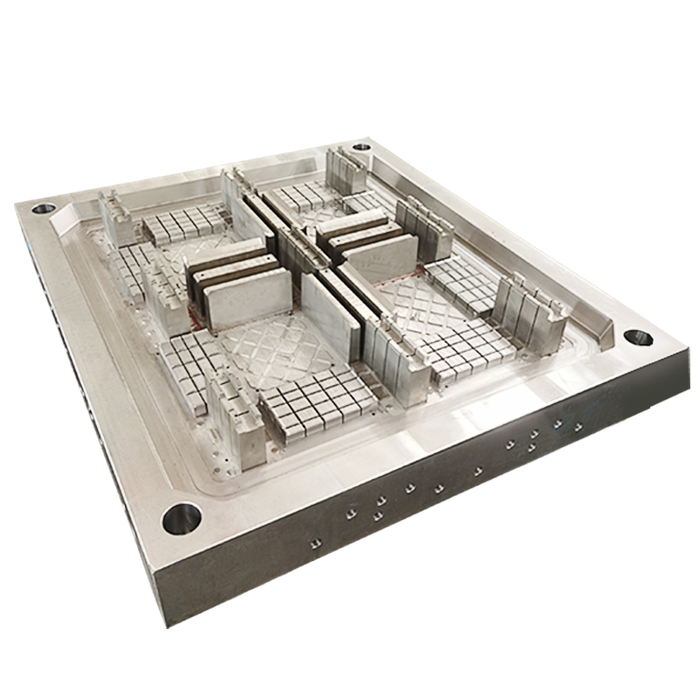

Plastic industrial pallet mold is an important equipment required for the production of plastic pallets. The tray mold consists of thimbles and inserts. It is critical that the pins fit perfectly with the inserts, and that the die has enough pins and links to ensure even force and minimal distortion. The materials used to make the molds, such as the hardness, toughness and machining costs of steel, should also be considered.

Plastic pallets are produced through a high-tech manufacturing process that ensures dimensional accuracy and consistent load ratings. This is different from wooden pallets, which are made from parts that can be inconsistent. In addition, the moulded plastic trays are produced by extreme pressure, ensuring the high quality of the product.

Metal

There are steps you can take to minimize the impact of metal industrial pallet molds on your business. While mold may not adversely affect your pallets in the short term, you should avoid letting it spread across your warehouse or storage area. For example, vacuum sealing wooden pallets can reduce the risk of mold contamination. Remember that mold needs warm temperatures to grow, so you should avoid storing your trays in hot or humid conditions.

Another way to keep your pallets from getting moldy is to check your pallets for mold. While mold seems unlikely, it can occur in almost any environment. Some industries don't allow mold to grow on their pallets, so you should be aware of your industry's mold tolerance policy. If your industry doesn't allow mold, you may need to dispose of your existing pallets and buy new ones.

Paper

The production of paper pallets requires the use of plastic pallet moulds. There are different types of these molds and they are used in various industries. The main difference between these types is their material type. One is made of thick-walled plastic and the other is made of transfer-molded pulp. Both types can support large weights without deforming. They also have steel inserts to spread the weight and provide extra strength.

Admittedly, mold is difficult to remove, but it can be remedied. The best way to handle pallet molds is to handle them as soon as they are made. This prevents any adverse effects on your pallet in the short term, but it is time consuming.

Injection mold

Injection molded trays are a good choice for packaging products. The process involves molding plastic or metal parts with two layers. The mold is divided into two different cavities by the rack and pinion transmission mechanism. The two cavities are then pushed out simultaneously by spring thrust. This process ensures uniformity and quality of the finished product.

Injection-molded plastic pallets are usually heavy-duty and have good integrity. This process allows high design flexibility and allows high dimensional accuracy. Industrial pallets made with structural foam injection molds have a honeycomb structure in the core and dense walls. In addition to this, pallets produced with this process have a high strength-to-weight ratio. Unlike high pressure injection molding, structural foam molding is cheaper and does not require steel molds. Plastic trays molded with structural foam can also be made from lighter materials.

chemical treatment

Chemical treatments are used to eliminate mold on wood packaging such as pallets and other wood products. These treatments work by protecting the wood from oxygen and moisture. Depending on the type, chemotherapy can take effect within a few weeks to several months. However, chemical treatment can be expensive and not all pallet suppliers can afford it.

Chemical treatments are invaluable tools for preventing mold growth on industrial pallets. They are also called "preventive fungicides" because they help seal the wood from oxygen, one of the main factors in mold growth. Chemical treatments are not permanent and should be used sparingly.

Customized Plastic Pallet Mould

Customized Plastic Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى