King Mold is a world-renowned high-tech injection mold manufacturer with unique management concepts and development directions, and is committed to becoming an innovative enterprise in injection mold and plastic molding technology.

King Mold is a joint-stock plastic injection mold enterprise. Its members include technical personnel, QC personnel, project managers, business managers, machining masters and other management team leaders, as well as employees who have made great contributions and innovations to the company. This is also the main reason for King Mold's high quality and on-time delivery. When a new member joins the King Mold family, our first training content: How should a qualified mold maker make a good pair of molds?

How to make a pair of injection molds?

In order to make a perfect injection mold, the first step is the design analysis of the plastic product, which is also a crucial step.

If there are defects or mistakes in the design of plastic products, the later work will be wasted or even wasted. 5 minutes of design in front of the computer is equivalent to 5 weeks in the workshop. Therefore, in order to make a good mold, the early design analysis and inspection of plastic parts must be 100% strict, and then 100% optimized.

Good mold design is the cornerstone of a good mold.

There is no best mold design in the world, because all designs have a lot of room for optimization, we should spend more time checking and improving mold design to improve mold quality. By the same token, 5 minutes of mold design in front of the computer may equal 5 weeks of work by a shop floor person. Therefore, the foundation of a good mold production depends on a rigorous mold design.

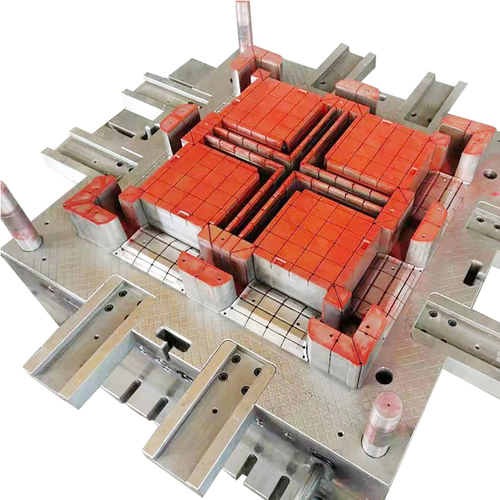

A qualified mold supplier has very strict control over the processing of molds and all mold parts, and will carry out dimensional inspection in each link of mold processing to ensure that the dimensions of all parts are within a reasonable tolerance range. Therefore, if a mold maker does not pay attention to dimensional control, it will not be a qualified mold maker.

A qualified mold supplier is very familiar with the properties of steel, and the purchase and control of steel is also very strict. What kind of steel material should be selected for different positions, some steel materials and sliding parts that are in contact with the surface of the product, we will make reasonable use of the hardness difference between the steel materials, and will make better material selection and matching, so that the life of the mold is longer. .

A qualified mold supplier is based on rich mold manufacturing experience and accumulation of technology. King Mold will carry out small batch order production before shipment to ensure that the mold can be produced normally in the customer's factory.

King Mold people always keep the above content in mind, thinking and learning every day. King Mold has strong technical support and strict production management system, and has been focusing on improving production capacity, step by step, to provide customers with satisfactory, high-quality and valuable injection molds!

English

English عربى

عربى