Sale OEM Injection Pallet Molded Boxes Mould Manufacturer

In the fast-paced world of manufacturing, the efficiency of the supply chain is paramount. One often overlooked component that can significantly impact this efficiency is the packaging used to protect and transport goods. Sale Injection Molded Boxes have emerged as a game-changer in this regard, offering a range of benefits that can streamline operations and reduce costs. This article delves into the impact of injection molded boxes on supply chain efficiency and how they can be leveraged to enhance overall performance.

Injection molded boxes are designed to fit the specific dimensions and requirements of the products they house. This level of customization ensures that each box is tailored to protect its contents, reducing the risk of damage during transit. The consistency of these boxes also simplifies the process of loading and unloading, as they can be uniformly stacked and arranged.

The strength and durability of injection molded boxes are unmatched by many other forms of packaging. These boxes are made from high-quality materials that can withstand the rigors of shipping and handling. The robust construction of OEM Box Mould provides ideal protection for delicate or heavy items, reducing the likelihood of damage and the associated costs of replacement or repair.

Injection molded boxes are designed to fit snugly around the products they contain, reducing the amount of unused space within the box. This space optimization not only reduces the amount of material needed for packaging but also allows for more efficient use of storage and transportation space, resulting in cost savings and a reduced carbon footprint.

Despite their strength, injection molded boxes are lightweight, which is a significant advantage in the supply chain. Lighter packaging reduces the overall weight of shipments, resulting in lower transportation costs and a smaller environmental impact. This lightweight design also makes handling and moving the boxes easier for workers, reducing the risk of injury and improving productivity.

The initial investment in injection molded boxes may be higher than other packaging options, but the long-term cost savings are substantial. The durability of these boxes means they can be reused multiple times, reducing the need for frequent replacements. Additionally, the reduced need for additional protective materials, such as bubble wrap or foam, further contributes to cost savings.

Injection molded boxes are often made from recyclable materials, making them an environmentally friendly choice for packaging. The reusability of these boxes also reduces waste, as fewer boxes are discarded after a single use. Manufacturers can further enhance the sustainability of their supply chain by choosing suppliers that prioritize eco-friendly production methods and materials.

Custom injection molded boxes offer a platform for branding and marketing. The boxes can be designed with company logos, colors, and other branding elements, creating a professional and cohesive appearance. This not only enhances the company's image but also provides an additional marketing tool that can help to increase brand recognition and customer loyalty.

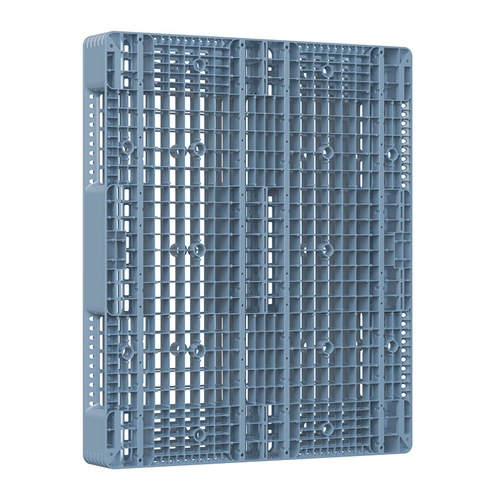

The standardized nature of Pallet Mould Manufacturers can simplify inventory management. With consistent sizes and shapes, it becomes easier to track and manage stock levels, reducing the risk of overstock or stockouts. This improved inventory management can result in better planning and forecasting, contributing to a more efficient supply chain.

Injection molded boxes protect from environmental factors such as moisture, dust, and temperature fluctuations. This protection ensures that products remain in ideal condition throughout the supply chain, reducing the risk of damage and spoilage.

In conclusion, the integration of injection molded boxes into the supply chain is a strategic move for manufacturers seeking to enhance efficiency and sustainability. These innovative packaging solutions not only protect products during transit but also contribute to a more streamlined and cost-effective logistics process.

English

English عربى

عربى