Sale OEM Plastic Reusable Pallets Mould Maker

In the dynamic landscape of modern manufacturing, the Plastic Pallet Mould plays a crucial role in streamlining production processes and enhancing efficiency. The integration of the Sale Plastic Pallet Moulds in the manufacturing sector has led to significant improvements in the handling, storage, and transportation of goods, thereby contributing to the overall productivity and sustainability of the industry.

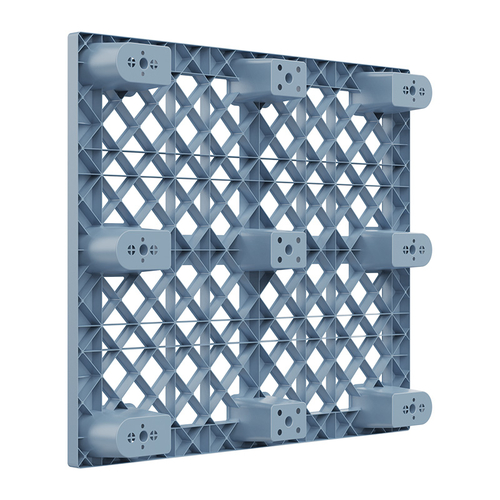

The Plastic Pallet Mould is a specialized tool used in the production of plastic pallets, which are indispensable in various manufacturing and logistics operations. The design and functionality of these moulds are tailored to meet the specific needs of different industries, ensuring that the plastic pallets are robust, durable, and versatile. This article delves into the role of Plastic Pallet Moulds in modern manufacturing, highlighting their significance and the benefits they offer.

The development of Plastic Pallet Moulds has been driven by the need for more efficient and sustainable solutions in material handling. Traditional wooden or metal pallets, while functional, posed challenges in terms of weight, durability, and environmental impact. The advent of it has addressed these issues, resulting in the widespread adoption of plastic pallets in manufacturing and logistics.

The design of OEM Plastic Reusable Pallets is a complex process that involves a deep understanding of material properties, manufacturing processes, and user requirements. The choice of plastic material for the mould is critical, as it affects the strength, weight, and durability of the product. The shape and structure of the mould determine the form and functionality of the plastic pallet, including its load-bearing capacity and stability. The mould should be easy to use, allowing for quick and efficient production of plastic pallets. The ability to customize the mould to meet specific industry requirements is essential for meeting diverse manufacturing needs.

The functionality of Plastic Pallet Moulds is a direct result of their design and the materials used. Plastic pallets produced using these moulds are designed to withstand heavy loads and harsh conditions, ensuring long-term use. The moulds can be designed to produce pallets suitable for a wide range of applications, from food and beverage to automotive and pharmaceutical industries. The use of it reduces production costs by reducing material waste and reducing the need for frequent replacements. Plastic pallets are often recyclable, contributing to a more sustainable manufacturing process.

The integration of Plastic Pallet Moulds in manufacturing has brought about several benefits. The use of plastic pallets streamlines material handling processes, reducing the time and effort required for loading, unloading, and transportation. Plastic pallets are less prone to damage and do not pose the same safety hazards as wooden or metal pallets, such as splinters or rust. The long-term cost savings associated with the use of plastic pallets, due to their durability and low maintenance requirements, are significant. The recyclability of plastic pallets and the reduced environmental impact of Plastic Pallet Moulds contribute to a greener manufacturing process.

Despite the numerous advantages, the use of Pallet Mould Makers also presents certain challenges. The cost of acquiring high-quality Plastic Pallet Moulds can be substantial, particularly for small-scale manufacturers. Ensuring that the materials and processes used in the production of plastic pallets meet industry standards and regulations can be complex.

To address these challenges, manufacturers can Opt for high-quality Plastic Pallet Moulds that offer long-term value and reduce the need for frequent replacements. Collaborate with experienced suppliers and manufacturers to ensure compliance with industry standards and practices.

English

English عربى

عربى