There are many factors you need to consider when deciding to invest in plastic pallet molds. These include cost, mold type and draft slope. Also, the correct model must be selected for the application you need. These tips will help you find cost-effective molds that meet your needs.

Injection tray mold

Injection tray molds are used to manufacture plastic trays for various products. This mold can produce both single-sided and double-sided pallets. These molds can vary in size and shape. Also, everyone has a different set of instructions. The main difference between the two molds is the type of plastic they use.

In addition to traditional single-sided pallet molds, injection molding pallet molds can also be customized according to your requirements. Xinnuo Mould has many years of experience in designing and manufacturing plastic pallet moulds. Its product range includes medium and large injection tray moulds. It is also a leading supplier of plastic molds and custom molds.

Injection tray mold is an indispensable equipment in the tray production line. It consists of upper and lower mold body and injection mechanism. The upper body is used to create a closed cavity, and the lower body is used to inject plastic into the cavity. Once the injection process is complete, the entire tray is complete.

release slope

The demoulding slope of the plastic tray mold refers to the amount of material that is demolded during the mold making process. It varies between 0 and 1.5 degrees. Reinforced plastics have larger slopes, while easy-release plastics have lower slopes. Different parts of the tray require different release slopes, but most manufacturers choose a release slope of one or two degrees.

The demoulding slope of the plastic tray mold is determined by two factors, the cooling water temperature and the plastic tray mold temperature. Lower temperatures result in flatter half trays, while higher temperatures result in higher warpage. Both effects were observed in simulations with saddle-shaped warping of the lower half of the plastic tray mold.

Another important factor of the plastic pallet mold is its ability to provide a high degree of rigidity. The resulting plastic pallets are highly impact and damage resistant. Plastic trays can be injection molded, thermoformed, compression molded or rotationally molded. With the right mold, plastic pallets can have advanced designs and improve their overall strength-to-weight ratio.

cost

In China, you can buy plastic pallet molds at very low prices. You can buy such molds from manufacturers who specialize in plastic pallets. You can also get factory-made plastic pallet molds for a very low price.

Plastic tray molds can be manufactured using injection molding, thermoforming and vacuum forming. However, injection molding is only suitable for mass production. Tooling cost and production capacity will determine which method is right for you. You also need to decide if thermoforming is better for your specific needs.

Blow molding is another method of making plastic pallets. This process is ideal for making pallets that can withstand temperatures up to 40 degrees Celsius. Plastic trays produced by blow molding are very hard and durable and are not easily damaged. They also have excellent impact resistance. They are lightweight, strong and suitable for cold chain supply procedures.

application

A plastic pallet mold is a tool used to shape plastic materials into pallets. During the manufacturing process, raw plastic is melted and forced through a mold. After a period of cooling, the tray is ejected from the mold. Plastic pallets usually consist of two layers: a honeycomb core and a rigid outer shell. They are about 10% to 30% lighter than solid plastics.

The process also produces a plastic pallet that won't break down over time. Because these processes may damage the product. Plastic trays also have consistent dimensions, which is important when you need to store and retrieve products. This makes them a great choice for these applications.

Several factors must be considered when designing a mold. For example, plastic pallets must withstand heavy loads, so they must be shaped strong enough to carry the weight. Additionally, they must be strong enough to prevent damage during shipping. Therefore, the multi-point gate of the plastic tray mold must be carefully designed and tested. Additionally, defects on welds and multi-point gates can affect the overall strength of the part. In addition, multi-gate injection molds are required to manufacture large plastic trays. This feature can use multiple injection gates at the same time and fill multiple materials at once.

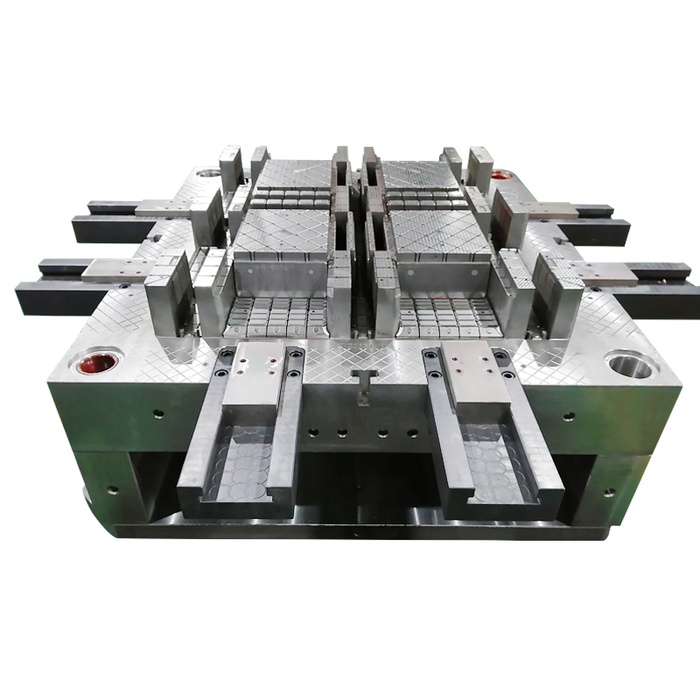

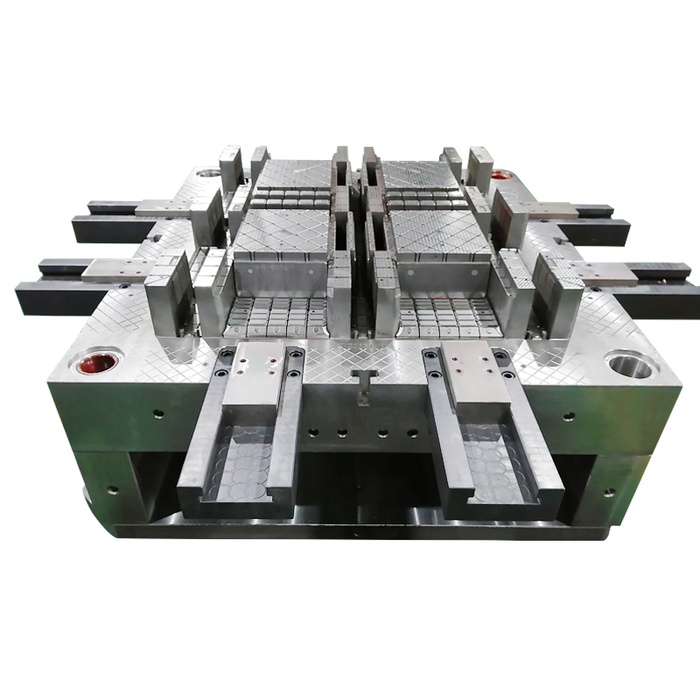

Assembled Flat Stackable Heavy Duty Pallet Mould

Assembled Flat Stackable Heavy Duty Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى