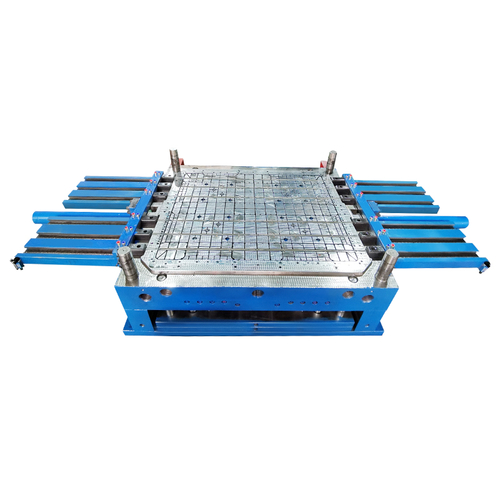

King Mould is a professional supplier of pallet moulds. From the three-dimensional modeling of the product to the first trial of the mold, we strictly control the manufacture of every step and insist on making high-quality molds. Here are the steps we take to make a pallet mold:

1. 3D design analysis of pallet

After we receive the customer's product design, we will immediately convene all relevant technical personnel to analyze its shortcomings and possible problems during processing. For example, the demolding slope, strength, plastic filling, deformation, wall thickness, skin texture, etc. are analyzed. After these discussions, the mold flow analysis is carried out, and if there are any problems, we will immediately get in touch with the customer and provide solutions or suggestions.

2. Pallet mold design technical meeting

All relevant personnel will participate in the new mold design technical meeting. At the meeting, we will put forward all the technical points, such as: the use of steel materials for mold parts, the basic structure of the mold, the plastic material and its melt index, the special requirements of customers, the parameters of the injection molding machine and the processing steps of the parts and so on.

3. Pallet mold design inspection

After the pallet mold is designed, the mold design review department will review the design. These audits include: * Mold structure inspection * Mold movement and guide system inspection * Mold injection system inspection * Mold cooling system inspection * Mold ejection system inspection * Mold vulnerable parts inspection.

4. Inspection of pallet mold steel

After the design of the tray mold is confirmed by the customer, we start sampling and testing the steel material with high-quality testing equipment to ensure that there are no cracks or impurities. And the steel hardness tester can measure whether the hardness of the steel is qualified or consistent.

5. Quality monitoring during pallet mold processing

In the process of mold processing, we also carry out basic quality control on steel materials. The processing is divided into three steps: the first step, rough machining; the second step, semi-finishing of some precision molds; the third step is high-speed milling and finishing. We have always paid attention to the anti-deformation control of steel during processing.

6. Dimensional inspection of pallet mold after processing

After the mold is processed, Wang Mould has two coordinate measuring instruments and one projection measuring instrument to measure the dimensions of the mold cavity, core and other parts. The qualified ones will be sent to the assembly workshop, otherwise the molds will be reworked.

7. Quality control of pallet mold assembly Our quality inspectors and project managers will conduct quality control of mold assembly.

8. Inspection before the first mold trial

English

English عربى

عربى