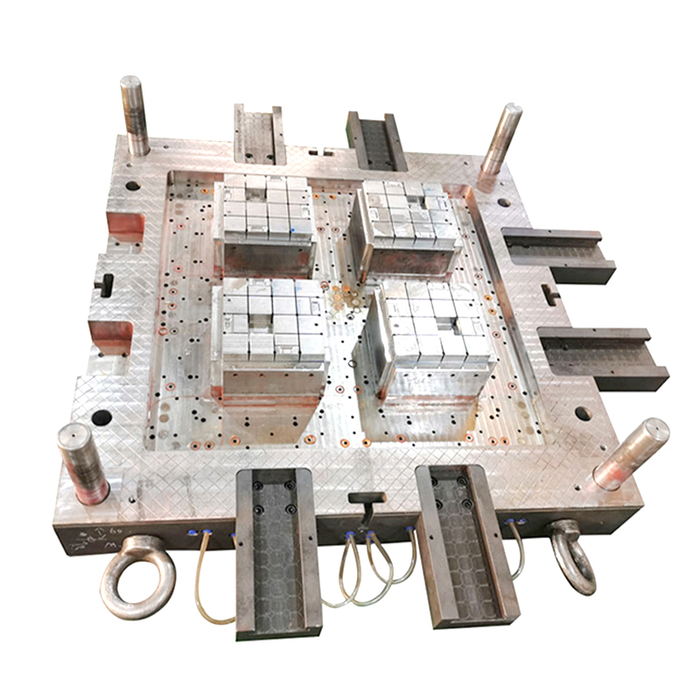

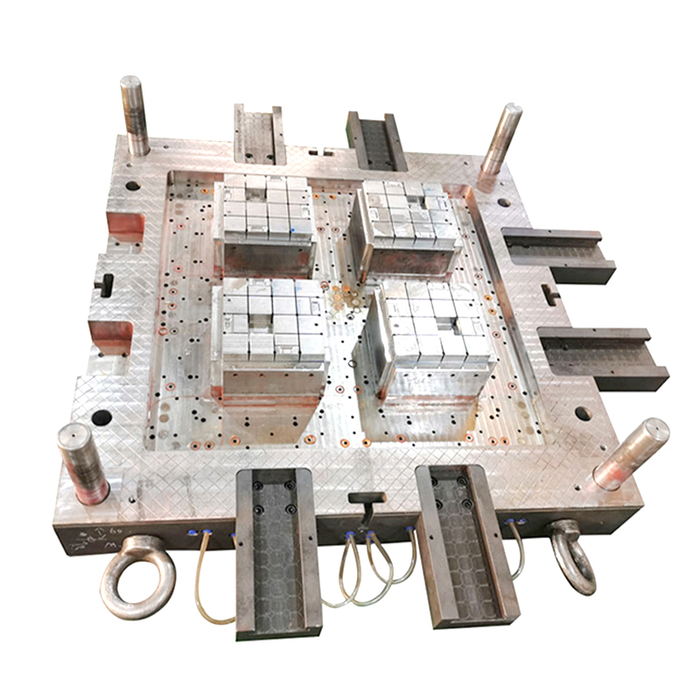

Do you know the grade of plastic tray mold? What are the requirements for the different levels? Today Jinshang came to sort out the level requirements of different molds, hoping to bring you some help.

First class plastic pallet mold

The first-level mold quality must be able to achieve one million or more mold opening times. At the same time, the mold is required to use good raw materials and accessories.

1. Have a specific mold structure design (with computer graphics and models);

2. The mold base hardness must be at least HB280;

3. The hardness of the core of the plastic tray mold must not be lower than HRC50, and all rows and accessories must be hardened;

4. There must be a thimble with a center support and side handle (the ejection system guide structure);

5. The rows need to be equipped with wear-resistant sheets;

6. The temperature control performance is monitored reliably, and it is installed on the mold core or bit line;

8. Positioning locks should be added to the position of the parting surface.

Secondary Plastic Pallet Mold

1. There must be more than 500,000 times of mold opening;

2. It is recommended to do detailed mold design;

3. The mold base hardness must be at least HB280;

4. The hardness of the mold core must not be lower than HRC48, and all rows and accessories need heat treatment;

5. The performance of the temperature control monitor is reliable, and it is installed in the mold core or row position;

6. The position of the parting surface should be locked with a positioning lock.

Three-Stage Plastic Pallet Mold

1. The plastic tray mold must have more than 250,000 times. This is a general mold requirement.

2. It is recommended to do mold design;

3. The mold base hardness must be at least HB165;

4. The mold core must be at least HB280;

Four-Stage Plastic Pallet Mold

This is a low-production mold, generally without any special requirements, but still good mold quality and customer approval.

1. About 10,000 injections are required.

2. It is recommended to do mold design;

3. The mold base may be common copper or aluminum;

4. The core of the mold can be made of aluminum or steel under the consent of the customer.

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)