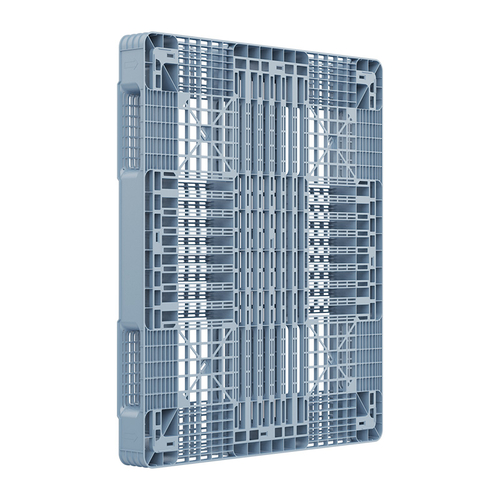

A pallet mold is a type of mold used to create pallets, which are flat transportation structures used to support and move goods and materials. Pallets are typically made of wood, plastic, or metal and are used in a wide range of industries, such as logistics, warehousing, and manufacturing.

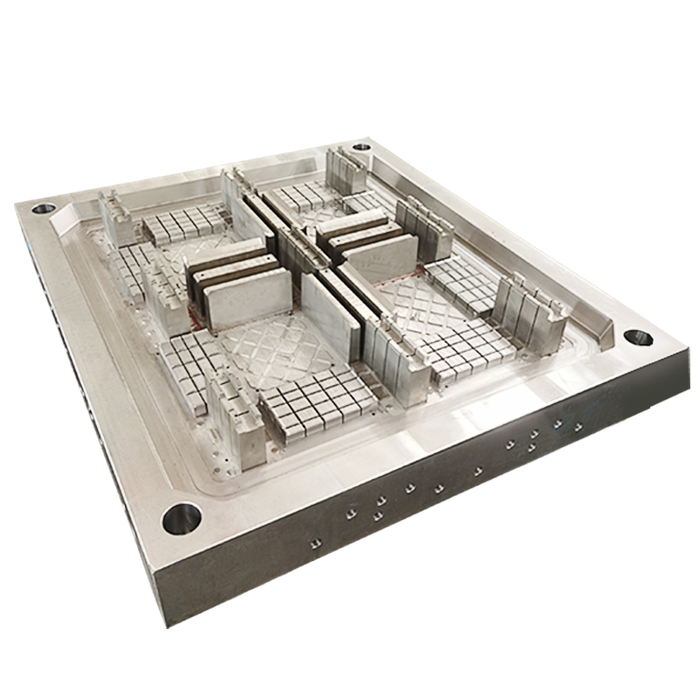

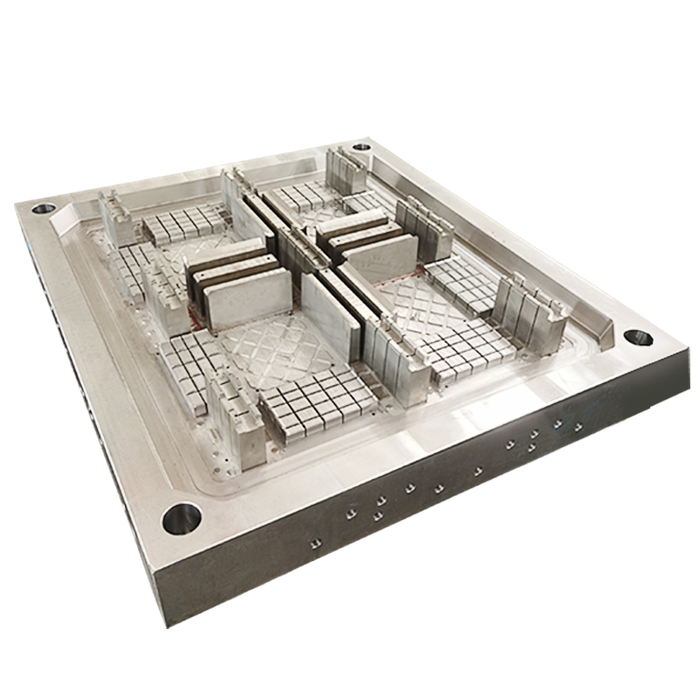

A pallet mold is a metal or plastic tool that is specifically designed to shape and form the raw materials into the desired pallet shape. The mold is typically made up of two halves, a top and bottom, which are clamped together to shape the pallet. The raw materials, such as plastic or wood, are placed in the mold and then subjected to heat and pressure to form the pallet.

Pallet molds are commonly used in the manufacturing of pallets, and they come in a variety of different designs and sizes to accommodate different types of pallets. They can be used to create standard or custom-designed pallets, depending on the specific needs of the customer.

Pallet molds are typically created using computer-aided design (CAD) software, which allows for precise and accurate manufacturing. They are also made of durable materials such as aluminum or steel, which can withstand the high temperatures and pressures involved in the molding process.

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets.

English

English عربى

عربى