Modern mold design and manufacturing is: in the environment of mold production process control and management, on the basis of highly standardized mold technology, the implementation of mold information, digital design and manufacturing process. That is, the implementation of mold CAD/CAE/CAM, the so-called mold design and manufacturing integration process. in:

CAD: refers to the process of establishing a digital model of the mold part, its structure and the mold structure system with the help of software.

CAM: Refers to formulating the forming part's surface forming processing code, setting the forming processing process conditions and the forming part processing program according to the digital model of the part and its structure. And transfer this information to CNC machine tools for digital processing.

CAE: refers to the use of software to simulate and simulate the mold shape, mold structure system and structural parameters, that is, to implement virtual design and molding processing to verify the CAD/CAM designed mold structure system and molding. Correctness and rationality of processing codes and processing programs.

CAD and CAE software are based on the comparison of empirical data, empirical formulas and theoretical data and formulas to form part modeling, mold system structure and parameters, part forming process and parts (punching parts, plastic parts, etc. ) Simulation of the forming process, simulation digital model or CAD, CAE software.

mold design

In the period of hand-crafted mold making and in the early stage of industrial mold manufacturing, mold design was not carried out, and molds were manufactured by relying on the experience and skills of molders. With the development of the industry, the application of molds is becoming more and more extensive, the performance and quality requirements of molds are becoming higher and the production technology is constantly improving. Design and draw the mold structure system diagram (general structure diagram) and parts drawings, clarify the design requirements and manufacturing technical conditions, which are the first priority and core technology in the mold production process, and have been evolving to the present.

However, with the advancement of the computer and CNC machine tool industry and the wide application of CNC machine tools such as machining centers, the mold design methods and methods have produced substantial and breakthrough progress. The mold design includes the following three aspects: mold shape and shape Its structure design, mold structure system design, mold structure parameter calculation and setting. Mold design process and content.

mold making

Using computer aided to formulate the manufacturing process (CAPP) of each pair of molds, and analyze it (CAPPE) to optimize it. At the same time, the quality, man-hour and cost of the manufacturing process are controlled (CAPPC), so that the mold CAM/CAPPE/CAPPC digital manufacturing technology system is formed.

Mold CAM/CAPPE/CAPPC system is the main way of modern mold manufacturing, and it is an integral part of mold CAD/CAE/CAM digital design and manufacturing technology. To this end, it is necessary to study and analyze the content of modern mold manufacturing technology, that is, the content of information and digital manufacturing technology: mold manufacturing process design; mold part manufacturing process and its forming process; mold standard parts, components and general auxiliary mechanisms. Procurement and manufacturing; mold assembly and its assembly process; mold manufacturing process control and management.

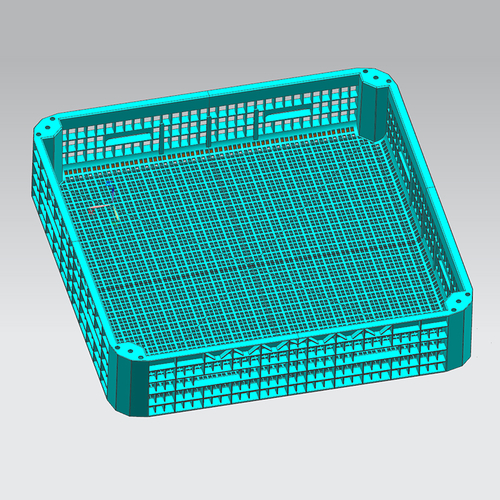

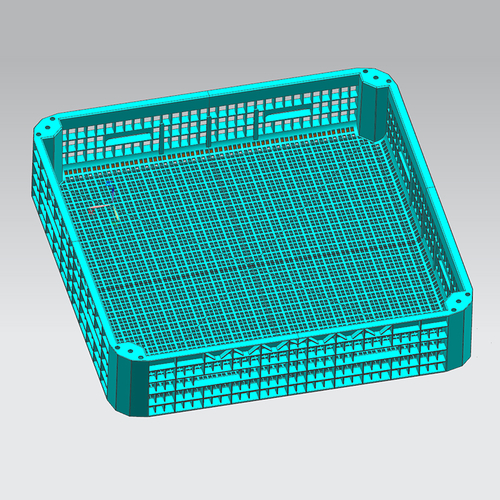

As professional Box Pallet Mould manufacturers and Box Pallet Mould factory in China -King Mould specialize in making custom Box Pallet Mould. King Mould locates in Taizhou city, "the hometown" of Chinese plastic moulding , about half an hour by car from Taizhou airport and ten minutes from Taizhou Train station.

China Mould maker King Mould equipped with innovative, high-tech equipment and high-class CAD/CAE/CAM system. With experienced technicians strictly maintain and operate every process of production, guaranteeing that we have a consistent and effective system in order to meet high quality needs.

As professional Box Pallet Mould manufacturers and Box Pallet Mould factory in China -King Mould specialize in making custom Box Pallet Mould. King Mould locates in Taizhou city, "the hometown" of Chinese plastic moulding , about half an hour by car from Taizhou airport and ten minutes from Taizhou Train station.

China Mould maker King Mould equipped with innovative, high-tech equipment and high-class CAD/CAE/CAM system. With experienced technicians strictly maintain and operate every process of production, guaranteeing that we have a consistent and effective system in order to meet high quality needs.

English

English عربى

عربى

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)